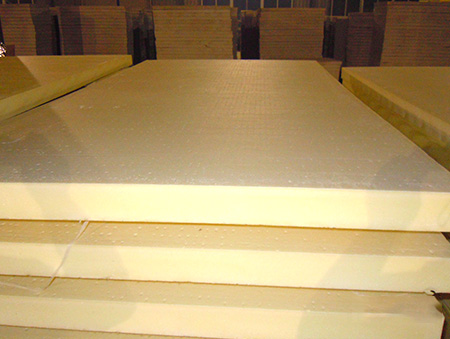

Polyurethane foam temperature requirements

Temperature control during polyurethane foaming is one of the key factors to ensure the quality and performance of foam. Foaming temperature usually involves the following aspects:

1. Raw material temperature:

Before polyurethane foaming, the temperature of raw materials such as polyols and isocyanates needs to be controlled within a certain range to ensure uniform mixing and smooth reaction. Usually, the raw material temperature should be controlled between 20°C and 25°C.

2. Ambient temperature:

The ambient temperature during foaming will also affect the performance of the foam. The ideal ambient temperature is usually between 20°C and 30°C, but this range can be adjusted according to the specific formulation and application.

3. Mold temperature:

For polyurethane foam that needs to be molded, mold temperature is an important parameter. The mold temperature is usually controlled between 40°C and 60°C to promote uniform expansion and curing of the foam.

4. Mixing temperature:

When the raw materials are mixed, the temperature of the mixture needs to be precisely controlled to ensure the smooth foaming reaction. The mixing temperature is usually close to the raw material temperature and is maintained at 20°C to 25°C.

5. Post-curing temperature:

The polyurethane foam after foaming needs a certain amount of time for post-curing to achieve the best physical and chemical properties. Post-curing can be carried out at room temperature, but heating can also be used to accelerate the curing process. The post-curing temperature generally does not exceed 60°C.

It should be noted that the above temperature range is a general guide, and it should be adjusted according to the specific polyurethane foam formula, equipment conditions and application requirements in actual operation. Manufacturers usually provide detailed operating guidelines and temperature control recommendations. During the foaming process, precise control of temperature is essential to obtain uniform and high-quality polyurethane foam.

Minimum temperature requirements

The minimum construction temperature of polyurethane foaming is usually recommended to be around 15°C. Too low temperature will result in poor material fluidity, difficulty in foaming, and deformation or shrinkage after molding.

1. Preheating polyurethane raw materials

In some cases, especially when constructing in cold seasons, it is recommended to preheat the polyurethane raw material tank in an environment of 30°C in advance. This ensures that the material has good fluidity when used, which is conducive to the formation of foam.

2. Temperature control during foaming

The preheating furnace temperature of the polyurethane foaming machine should be controlled at 30~50℃, and the foaming mold temperature should be controlled between 35~45℃. If the foaming mold temperature is too low, the foam system will have poor fluidity, long curing time, incomplete reaction, and possible cavitation. If the foaming mold temperature is too high, the plastic liner may be deformed by heat, and the reaction will be violent and difficult to control.

The suitable temperature range for polyurethane foaming is roughly above 15℃, preferably within the range of 20℃~28℃, and in actual operation, the temperature of the raw materials and the environment needs to be strictly controlled to ensure the quality and performance of the foam. In special circumstances, such as construction in cold seasons, the raw materials need to be preheated in advance to ensure the foaming effect.