Slab Jacking

Our polyurethane slab lifting raw material system breaks through the traditional rigid foam solution, upgrading the "rigid" system to a more resilient "tough" structure. It is not easy to crack under high-pressure environments and is suitable for a variety of complex foundation repair conditions.

What is Slab Jacking?

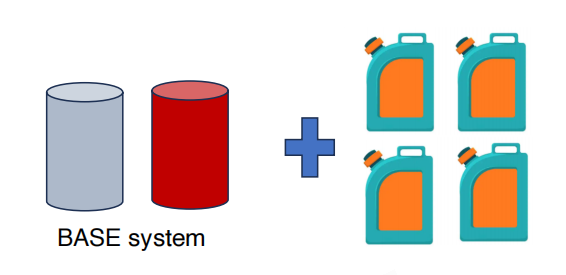

Base System Introduction Of Slab Jacking Material

Component | Appearance | Viscosity cps | Density kg/m3 |

Part A – Polyol | Yellow to light Brown Liquid | 320 | 1.00 |

Part B – ISO | Dark Brown | 240 | 1.24 |

Accelerator1 |

| 500 | 1.00 |

Fields Of Application

- Stabilisation of fractured rock, sands and gravels and land-fill materials

- Void filling

- Repair of concrete structures

- Fields of applicationControl of high volume water ingress

Features And Benefits

- Fast reacting material where structural strength or rigidity is required;

- System can cured with and without water condition, as a significant safety advantage;

- When in contact with water, the product forms a rigid foam. Without the presence of water, the product also reacts and forms a stiff, rubber-like material;

- Modification of the reaction can be achieved using a separately supplied accelerator and thixotropic agent to BASE PARTA system.

Technical Breakthroughs Of SPC Slab Jacking Material

We Offer One-stop Solution

We are committed to providing customers with one-stop solutions for raw materials and equipment, covering a full range of services from raw material procurement to equipment supply, helping enterprises to operate efficiently and reduce costs.

Slab Jacking Material Solution

Easy handles and reliable quality

- each accelerates will be precisely formulated

- It will be weighted in system house and small

packaged - The properties have been designed in lab, instead of

any ‘Inspiration’ on site; - Manual will be provided

Step 1:

Unpackage selected accelerator package and pour totally into drum

Step 2:

Mix for 10-15 mins ensure well

Step3:

- Ready to use

- 6 mons shelf life

- Selected properties

First Recommendation Of Slab Jacking Material

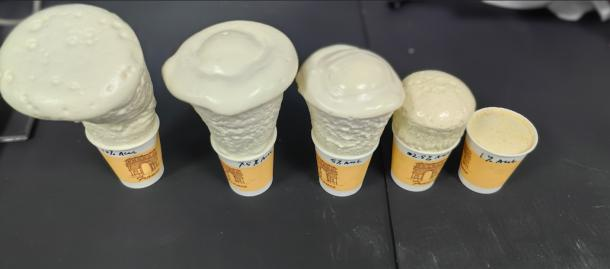

- Features low foam density and high gelling reactivity;

- Recommend foam density ~ 3 pound/ft3 with adding amount 5%wt;

Foam density under different Accelerator 1 adding level

Accl1 addition amount | 1.0% | 2.5% | 5.0% | 7.5% | 10.0% |

FBD kg/m3 | 191.50 | 79.80 | 48.80 | 43.31 | 38.79 |

- Foam Density: 48.8 kg/m³

- Cell Open Area: 0%

- Water Absorption: 0.36%

- Compression Modulus: 0.44 MPa

- Test Conditions:

- Sample Size: 50mm*50mm*50mm

- Compression Speed: 15mm/min

- Compression Rate: 10%

- Dimensional Stability: < 2%

- L: -0.12%

- W: 0.01%

- T: 1.16%

*Please check with SPC any other accelerators for properties adjustment.

Mudjacking vs. Slabjacking

Project | Mudjacking | Slabjacking (Polyurethane) |

Material | Cement mortar | Polyurethane foam |

Weight | Heavy | Lightweight |

Cure Time | Length | Quick |

Environmental Adaptability | Variation (wet soil/water sensitive) | Good (wet or dry) |

Cost | Low | High |

Construction Impact | Slow construction, long ground occupation | Quick application and quick return to service |

Support Given

Clients Rating

Money Saved

Awards won

Customer Cases Of Slab Lifting Solution

Our client is a construction company specializing in floor repair. Initially, using a traditional rigid foam system, they encountered problems such as uneven foaming and incomplete on-site curing. With support from our technical team and formula optimization, they adopted a next-generation Tough polyurethane system, significantly improving the foam’s permeability and compressive toughness, significantly enhancing construction stability.

The improved material’s excellent performance and successful construction results enabled the client to successfully win a bid for a foundation repair project from the local government, becoming a long-term partner in regional infrastructure restoration projects.